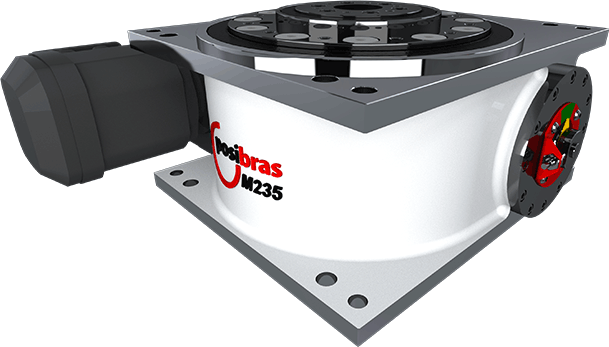

M235 | |

| Our M235 rotary indexing table is designed for applications that requires medium loads. Compact and lightweight, it can be easily installed with just 4 screws. It can be installed horizontally, vertically or inverted (upside down). Ideal for applications such as: – drill machines – milling – presses – welding – pallets positioning – foundry – special machines | |

| |

Technical details | |

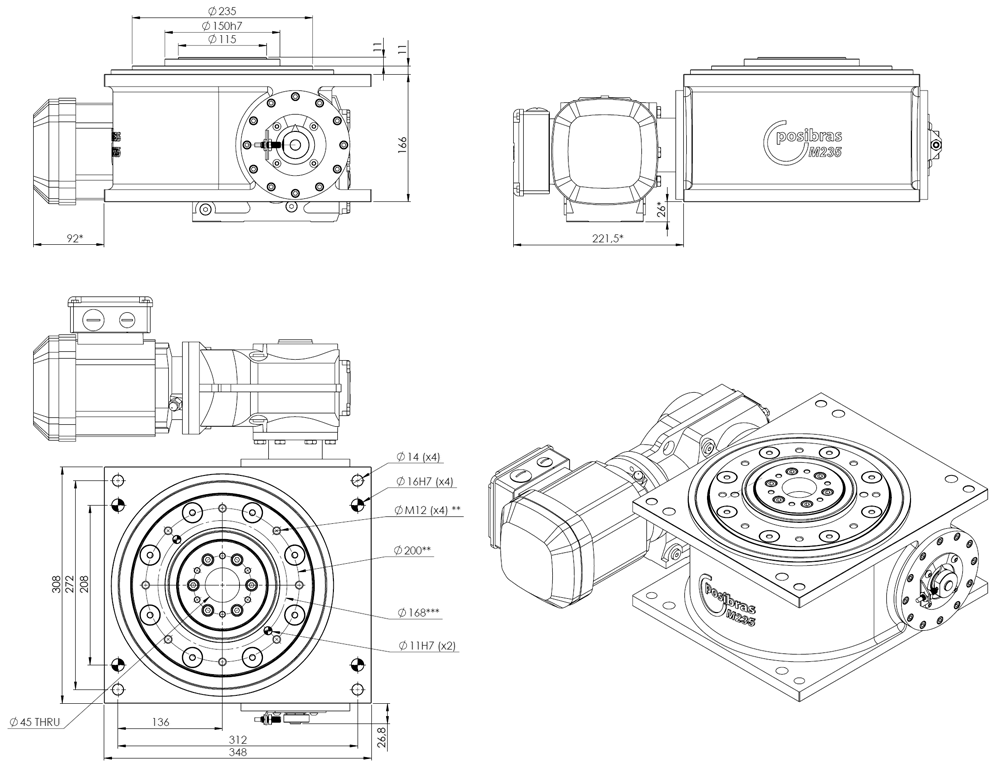

| Diameter of turntable: | 235 mm |

| Diameter of center opening: | 45 mm |

| Direction of rotation: | Clockwise , anticlockwise or alternating both |

| Number of indexes: | Indexed cam: 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 18, 20, 21, 22, 24, 26, 27, 28, 30, 32, 33, 36 (more option upon request), or Continuous cam |

| Motor voltage: | 220 V / 380 V / 440 V |

| Motor frequency: | 50 Hz / 60 Hz |

| Motor power: | 0.25 a 2.2 KW |

| Weight without gearmotor: | around. 40 Kg |

| Weight with gearmotor: | around. 60 Kg (vary according to the installed gearmotor) |

| Indexing accuracy: | ±0.014 mm at 50 mm center radius |

| Repeatability accuracy: | ±0.007 mm at 50 mm center radius |

| Inductive sensor: | PNP NA (10 V a 36 V) |

LoadsTo select which model is the best choice for your project, it needs to know the loads, the moment of inertia of the mass that will be moved, the time in seconds for the positioning and the number of stations (stops). This info can be sent to us by filling the fields of the menu Get a quote. Or if you prefer, send us an e-mail. | ||

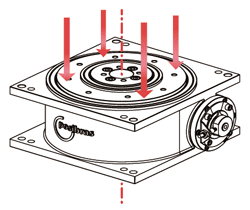

| A- Maximum axial load (*): Represents the total mass evenly distributed on the turntable (or total weight)(*) – the maximum total load refers to the forces on the turntable. This does not mean that the indexing table will be able to rotate this mass, as the rotation depends on three factors:

| 5.000 Kg |

| B- Maximum radial load: Represents forces perpendicular to the center of the rotating plate, generally exerted by actuators outside the indexing table, aligned to the center of this plate | 700 Kg |

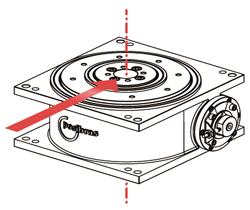

| C- Maximum vertical torque: It represents the unbalance of masses on the turntable, or the twisting of this turntable, usually caused by actuators outside the indexing table that exert axial force on only one side of the turntable | 5000 Nm |

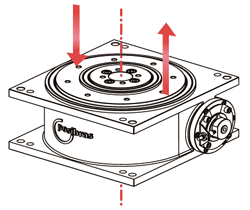

| D- Maximum horizontal torque: represents external forces in the direction of rotation of the index table, forcing the rotating plate to rotate or brake | 1600 ~ 2400 Nm |

Main dimensions |

in milimeters |

Gearmotor assembly position

|

Download the instructions manual clicking the icon below |